Selecting the right refractory materials is crucial for industries operating in high-temperature environments. Among these materials, zircon bricks stand out due to their exceptional thermal stability and resistance to thermal shock. This guide aims to delve into the intricacies of choosing and utilizing zircon bricks effectively.

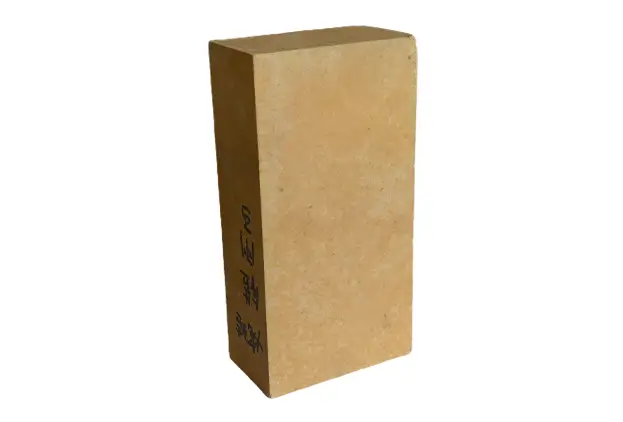

Zircon bricks are produced from zirconium silicate and are known for their unique properties that make them suitable for various industrial applications. With high melting points and resilience against aggressive molten materials, zircon bricks are ideal for use in furnaces and kilns.

1. High Thermal Stability: Zircon bricks can withstand extreme temperatures, making them essential for high-temperature refractory linings.

2. Thermal Shock Resistance: The unique crystal structure of zircon allows it to absorb thermal stresses without cracking or breaking.

3. Corrosion Resistance: Zircon bricks exhibit excellent resistance to chemical attack, which prolongs their lifespan in aggressive environments.

When choosing zircon bricks, several factors must be considered to ensure optimal performance:

Proper installation and maintenance of zircon bricks are vital for maximizing their performance. Here are some best practice guidelines:

Zircon bricks are an invaluable choice for industries faced with high-temperature challenges. By understanding their properties, selecting the right type, and following effective usage practices, enterprises can enhance performance, reduce downtime, and ensure durability in their operations. Making informed decisions when it comes to refractory materials like zircon bricks can lead to significant advantages in production efficiency.