As someone who has navigated the intricate world of high-performance materials, I understand the importance of choosing the right carbon brick refractory materials. Whether you're working on industrial projects or specialized applications, the selection of suitable materials can significantly impact performance. In this guide, I will share my insights on how to make informed choices tailored to your specific high-temperature needs.

Before diving into the selection process, it’s crucial to assess your unique application requirements. Consider temperature ranges, chemical exposures, and mechanical stresses that your bricks will face. Each application is different, and understanding these factors can lead you to the most appropriate carbon brick for your needs.

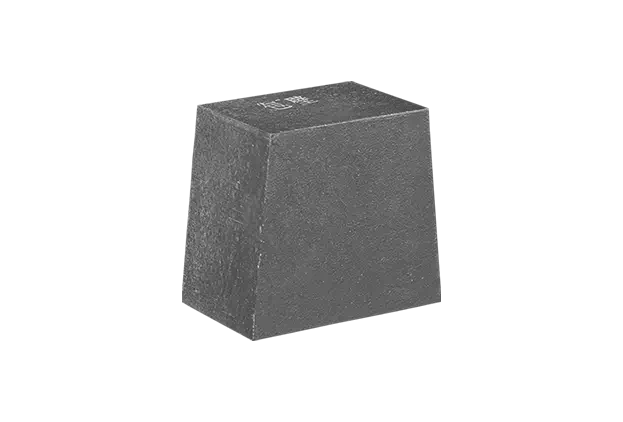

High-performance carbon bricks come in various grades, each with distinct characteristics such as thermal conductivity, strength, and density. Look for products that not only meet but exceed the specifications required for your application. A good strategy is to consult manufacturer guidelines and seek advice based on your project's specifics.

The composition of the carbon brick, including binder materials and additives, can greatly influence its performance under high-temperature conditions. For instance, some carbon bricks are designed with enhanced bonding agents to withstand thermal shock or corrosive environments. Choosing the right composition can extend the lifespan of your material, reducing maintenance costs and downtime.

As I reflect on my experiences, it’s essential to partner with reputable suppliers. Seek suppliers who not only deliver quality products but also offer comprehensive support during the procurement process. Review client testimonials, and do not hesitate to ask for product samples. A trustworthy supplier can provide insights that are invaluable to making the right choice.

In conclusion, selecting the right high-performance carbon brick refractory materials requires a thoughtful approach. By understanding your application needs, evaluating performance specifications, considering material compositions, and collaborating with reliable suppliers, you can make choices that lead to optimal performance and durability. Remember, the right material isn't just about meeting specifications—it's about investing in the future of your projects. Happy selecting!