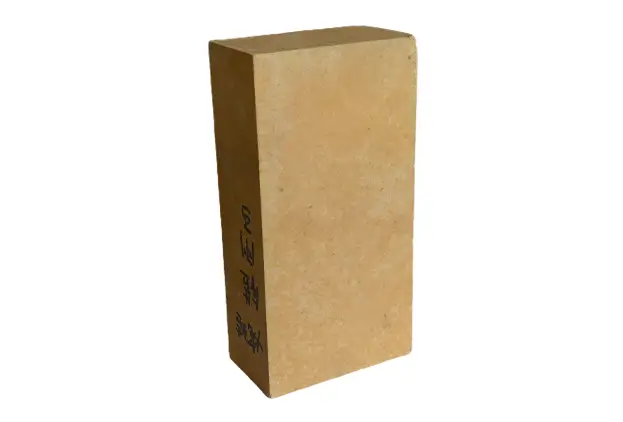

As I explore the fascinating world of zircon bricks, I can’t help but feel a sense of excitement about the technological breakthroughs that are shaping this industry. The advancements in zircon brick technology not only promise to enhance performance but also cater to an evolving market that demands more sustainable and efficient materials. Here, I share my insights into these recent developments and their implications for the market.

Zircon bricks, renowned for their durability and thermal stability, are witnessing remarkable innovation. One of the standout breakthroughs is the improvement in the production process, which now incorporates advanced techniques like chemical vapor deposition. This method enhances the structural integrity of zircon bricks, making them more resilient under extreme conditions.

Moreover, the introduction of nano-coatings has been a game changer. These coatings bolster the thermal resistance of zircon bricks, allowing them to withstand higher temperatures without compromising their structure. Personally, I believe this innovation could significantly expand their applicability across various industries, from metallurgy to energy production.

The current market landscape for zircon bricks is vibrant, driven by a surge in demand for high-performance materials. Industries are increasingly prioritizing efficient thermal management solutions, a trend that aligns perfectly with the capabilities of advanced zircon bricks. This is especially true in sectors such as aerospace and automotive, where heat resistance is crucial.

In my observation, the push for sustainability is further amplifying the need for zircon bricks. As companies commit to reducing their carbon footprint, the intrinsic properties of zircon bricks make them a preferred choice. Their longevity means fewer replacements are needed, aligning with the eco-friendly initiative many businesses are adopting.

While the future looks bright for zircon brick technology, certain challenges persist. The cost of production remains a concern, particularly for businesses seeking to transition to these advanced materials. However, the potential for innovative financing and collaborative partnerships can pave the way for broader adoption.

In conclusion, I believe that the technological breakthroughs in zircon brick manufacturing are not just enhancing product performance but are also setting the stage for a more sustainable and efficient future. As we continue to embrace innovation, the demand for zircon bricks will only grow, catalyzing further developments in this remarkable field.