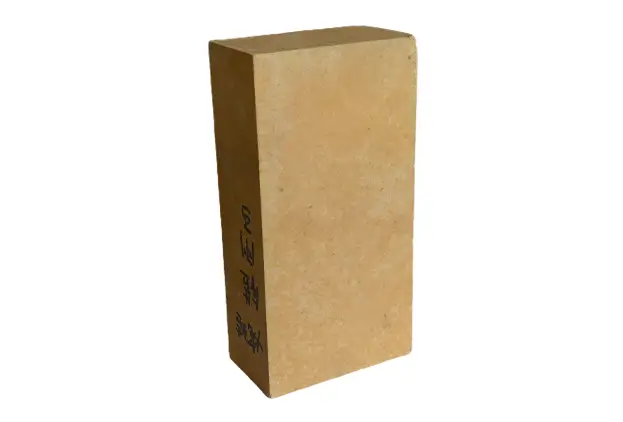

As I walk through the vibrant production floor of a glass manufacturing facility, the immense energy of the melting furnace surrounds me. The specialized equipment is primed for action, with temperatures soaring high, and the commitment to perfection echoing in every corner. It is here that refractory zircon bricks play a pivotal role, ensuring the integrity and efficiency of the glass-making process.

From my conversations with operators and engineers, it becomes evident that the reliability of refractory zircon bricks is unmatched. These bricks are engineered to withstand extreme thermal shocks—an essential characteristic given the dynamic temperature fluctuations within a glass furnace. The thermal endurance they provide not only enhances the operational lifespan of the furnace but also minimizes maintenance disruptions, allowing for continuous production and consistent quality.

Another remarkable quality of these zircon bricks is their resistance to corrosion, which is crucial in a glass furnace environment where corrosive agents can be prevalent. Observing the meticulous focus of the team working with these materials, I can't help but admire how they rely on the durability of refractory zircon bricks to protect against chemical reactions that could jeopardize the structure of the furnace. This characteristic builds an unswerving confidence among the operators, as they witness firsthand how these bricks stand the test of time and conditions.

Listening to customer feedback further emphasizes the value of refractory zircon bricks. Several clients have expressed not only satisfaction with the performance of these materials but also how they have drastically improved their product quality. One operator shared a heartfelt story of how using these bricks allowed them to reduce defects in their final glass products, a true testament to the impact of quality materials on production outcomes.

My journey through the glass production facility reinforced my belief in the critical role refractory zircon bricks play in enhancing operational efficiency and product quality. It is more than just a material; it is a trust forged between technology and craftsmanship, standing resilient against the formidable challenges posed by high temperatures and corrosive environments. As the glass industry continues to evolve, the steadfast reliability of refractory zircon bricks remains a key pillar supporting innovation and excellence in production.