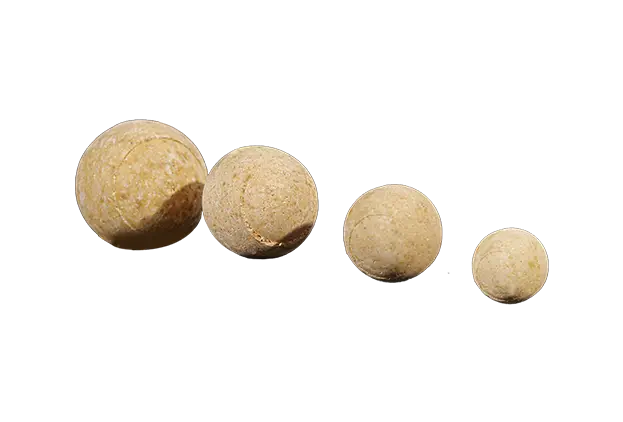

In the manufacturing landscape, the demand for materials that can withstand extreme conditions is critical. High Alumina Refractory Balls, with an exceptional alumina content, are specifically designed to perform in the most challenging industrial environments. These refractory balls excel in thermal stability, offering unparalleled resistance to temperatures up to 1900°C, making them suitable for versatile applications across various industries.

The primary features of High Alumina Refractory Balls include:

High Alumina Refractory Balls are versatile and find application in:

Used primarily in blast furnaces and heating Equipment, these refractory balls significantly boost energy efficiency.

Ideal for reactors and catalytic converters, they require high thermal stability and chemical resistance.

Essential in maintaining structural integrity in processes within the aluminum and copper industries.

Utilized in kiln linings for cement and glass production, ensuring longevity and efficiency.

Enhancing durability in boilers and furnaces, they are critical for reliable power generation.

In conclusion, High Alumina Refractory Balls offer a blend of thermal resistance, mechanical strength, and adaptability for various industrial applications. Their proven reliability and efficiency can significantly enhance productivity while ensuring the integrity of equipment. Adopting these versatile refractory solutions positions manufacturers to meet the challenges of today's demanding industrial environments.