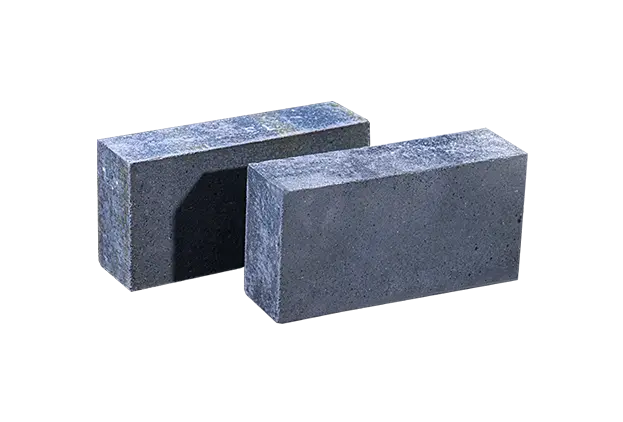

In the realm of high-temperature industrial applications, the demand for superior materials that can withstand extreme environments is greater than ever. High Performance Silicon Carbide Refractory Bricks are at the forefront of this need, offering exceptional thermal shock resistance and high durability.

Silicon Carbide (SiC) is well-known for its outstanding properties. These bricks are specifically engineered to excel in harsh environments, making them a reliable choice for various industries.

One of the hallmark features of these refractory bricks is their remarkable thermal shock resistance. This quality enables them to maintain integrity even under rapidly changing temperature conditions, an essential attribute for tasks involving heavy temperature fluctuations.

In addition to thermal stability, high wear resistance drastically minimizes material erosion. This characteristic is crucial in environments where long-term performance is essential, effectively reducing maintenance costs and downtime.

The versatility of Silicon Carbide Refractory Bricks enables their application across multiple sectors, including:

In the steel industry, these bricks are extensively used in blast furnaces and ladles due to their high durability, ensuring optimal performance under extreme conditions.

For the ceramics industry, particularly in kiln furniture and refractory linings, they provide stable structural performance that is critical during high-temperature processes.

The glass industry benefits significantly from these bricks, which deliver reliable solutions for melting and forming applications, particularly when dealing with aggressive environments.

With a myriad of benefits and a wide range of applications, High Performance Silicon Carbide Refractory Bricks stand out as a superior choice for industries looking to enhance their production efficiency and reliability. Investing in these bricks is investing in longevity and performance for any high-temperature industrial application.