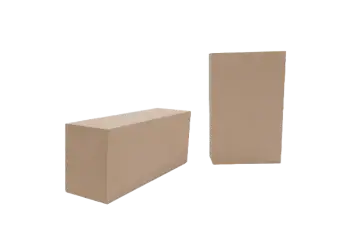

In today’s industrial landscape, efficiency and sustainability are paramount. One innovative solution gaining traction is Lightweight Clay Insulation Bricks, particularly for high-temperature applications. These bricks, crafted from a unique blend of chamotte and plastic clay, offer various benefits that industries such as steel, cement, glass, and electric power cannot overlook.

Rongsheng’s Lightweight Clay Insulation Bricks are engineered to provide superior thermal insulation. Their porous structure significantly reduces heat loss, contributing to lower energy consumption during industrial operations. This not only enhances sustainability but also leads to considerable cost savings — a critical factor for competitive industries.

With a maximum service temperature of 1400°C, these bricks are versatile enough to meet the demands of various high-temperature environments. Whether in steel manufacturing or cement production, the ability of these insulation bricks to withstand extreme conditions makes them a reliable choice.

The low bulk density of these bricks decreases the overall weight of kilns and furnaces, leading to significant savings in structural costs. Such a lightweight composition is especially advantageous in sectors like glass manufacturing, where optimal thermal efficiency is crucial.

These bricks have been adopted successfully across multiple sectors including chemical processing and electric power generation. Their robust mechanical strength and thermal shock resistance ensure a longer service life, thus offering a high return on investment.

In conclusion, Lightweight Clay Insulation Bricks represent a game-changing technology for high-temperature industrial applications. Their exceptional thermal properties, lightweight nature, and proven track record make them essential for modern industrial operations looking to achieve both efficiency and sustainability. Choose Rongsheng's lightweight clay insulation bricks for your facilities and experience the benefits first-hand.