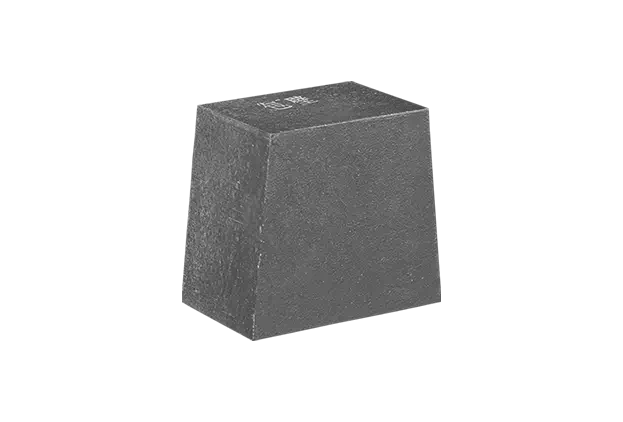

In the realm of metallurgy, the choice of refractory materials is pivotal for optimizing operational efficiency and longevity of equipment. Amongst the array of materials available, high-performance carbon brick refractories stand out due to their exceptional characteristics that cater specifically to the diverse needs of the industry. These unique materials not only fulfill the demanding requirements of high-temperature applications but also provide enhanced resistance to corrosion, one of the major challenges faced in metallurgical processes.

The unparalleled properties of high-performance carbon bricks include their capacity to withstand extreme thermal stress while maintaining structural integrity. Their unique molecular structure provides remarkable thermal conductivity, allowing for efficient heat transfer during metallurgical operations. Additionally, these refractories exhibit an impressive high-temperature corrosion resistance, crucial for areas exposed to reactive environments. This not only prolongs the lifespan of industrial equipment but also minimizes operational costs associated with frequent maintenance and replacements.

As the demand for higher efficiency and sustainability grows within the metallurgy sector, the need for specialized materials becomes increasingly relevant. High-performance carbon brick refractories are tailored to meet these demands, making them an essential component in various metallurgical applications, including blast furnaces, converters, and kilns. Their use not only enhances productivity but also contributes to reducing energy consumption, a crucial factor in today's environmentally conscious climate.

In conclusion, high-performance carbon brick refractories present a compelling solution for the challenges faced by the metallurgy industry. Their unique properties, coupled with the rising market demand for efficiency and sustainability, position them as a favored choice among industry professionals. As innovations continue to evolve, the role of these advanced refractories will undoubtedly become more significant, driving enhanced performance and contributing to a greener future in metallurgy.