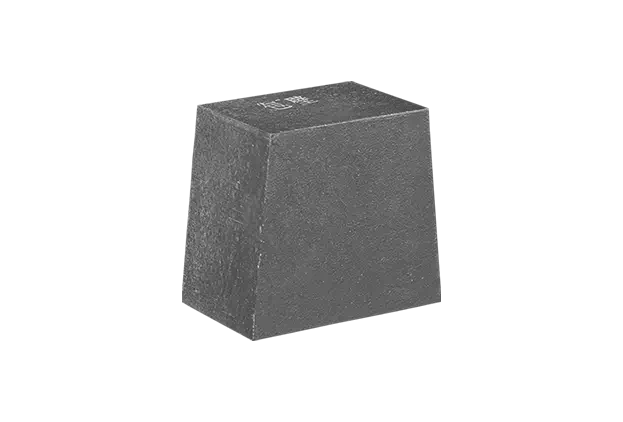

The metallurgical industry operates at extreme temperatures and aggressive chemical environments, which demands materials that can withstand these harsh conditions. High-performance carbon brick refractories have emerged as a superior choice due to their exceptional properties, making them indispensable in various metallurgical processes.

Carbon bricks are known for their high-temperature stability and remarkable resistance to thermal shock, which are crucial for maintaining the integrity of industrial furnaces. These materials exhibit outstanding chemical resistance, particularly against metal and slag corrosion, which is a common challenge in the metallurgical sector. Their ability to perform consistently over extended periods not only safeguards operational efficiency but also reduces the frequency of maintenance interventions.

One of the standout features of high-performance carbon bricks is their tenacity against high-temperature corrosion. In environments where molten metals and aggressive chemicals are present, traditional refractory materials often fall short, leading to premature failure and increased downtime. Carbon bricks, however, maintain their structural integrity and resist slag penetration, allowing for increased product yield and improved overall process efficiency.

The demand for high-performance carbon brick refractories continues to rise, driven by the ongoing growth of the metallurgical industry. As manufacturers strive for higher operational efficiencies and reduced production costs, the adoption of advanced refractory solutions has become essential. Furthermore, the increasing global emphasis on sustainability and resource conservation pushes industries to seek materials that enhance performance while minimizing waste.

High-performance carbon bricks align with sustainable practices due to their low waste generation and durability. By minimizing the frequency of replacements and maximizing service life, these materials contribute to reduced resource consumption and lower environmental impact. As a result, the metallurgical industry is placing greater trust in carbon brick refractories, not just for their performance, but also for their role in facilitating greener operations.

In summary, high-performance carbon brick refractories present significant advantages in the metallurgical sector through their unique properties and market relevance. Their high-temperature resistance, chemical durability, and sustainability features position them as the material of choice for modern metallurgical operations. As the industry evolves, these innovative refractories are poised to play a crucial role in shaping efficient and sustainable practices.