Catalytic reactions are at the heart of modern chemical manufacturing, playing a pivotal role in synthesizing various chemical products efficiently. Among the numerous components that influence these reactions, the materials employed within catalytic reactors are of paramount importance. High-alumina refractory balls emerge as crucial players in this landscape, significantly affecting reaction dynamics and overall efficiency.

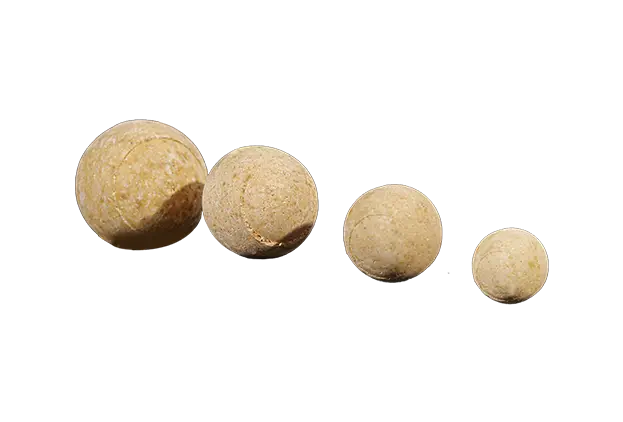

High-alumina refractory balls are specially designed materials composed primarily of alumina, known for their outstanding thermal stability and mechanical strength. These properties make them uniquely suited for high-temperature environments often encountered in catalytic reactions. Unlike traditional support materials, high-alumina variants offer superior resistance to thermal shock, ensuring longevity and consistent performance in catalytic systems.

One of the primary benefits of incorporating high-alumina refractory balls in catalytic reactors is their ability to enhance reaction efficiency. Their high surface area and porosity facilitate better contact between reactants and the catalyst, leading to increased reaction rates. The structural integrity of these balls allows for optimal flow patterns within the reactor, minimizing dead zones and ensuring a uniform distribution of reactants.

In addition to improving reaction efficiency, high-alumina refractory balls contribute to the optimization of catalyst performance. By providing a stable and supportive environment, they protect catalysts from deterioration due to thermal stresses and chemical interactions. This not only extends the lifespan of the catalysts but also maintains their activity and selectivity over prolonged periods. Consequently, industries utilizing these materials can achieve higher yields and reduced operational costs.

The application of high-alumina refractory balls in catalytic reactors is significant in various industrial sectors, including petrochemicals, pharmaceuticals, and environmental engineering. The ability to conduct reactions at higher efficiencies translates to less energy consumption and lower emissions, aligning with global sustainability initiatives. As industries continue to prioritize eco-friendly practices, the role of these refractory balls will likely expand further.

In summary, high-alumina refractory balls are not merely inert fillers in catalytic reactors; they are essential components that profoundly impact reaction dynamics and efficiency. By enhancing catalyst performance and facilitating better reactant interaction, they play a crucial role in optimizing industrial processes. As the demand for efficiency and sustainability in chemical manufacturing grows, the significance of high-alumina refractory balls is poised to become even more pronounced.