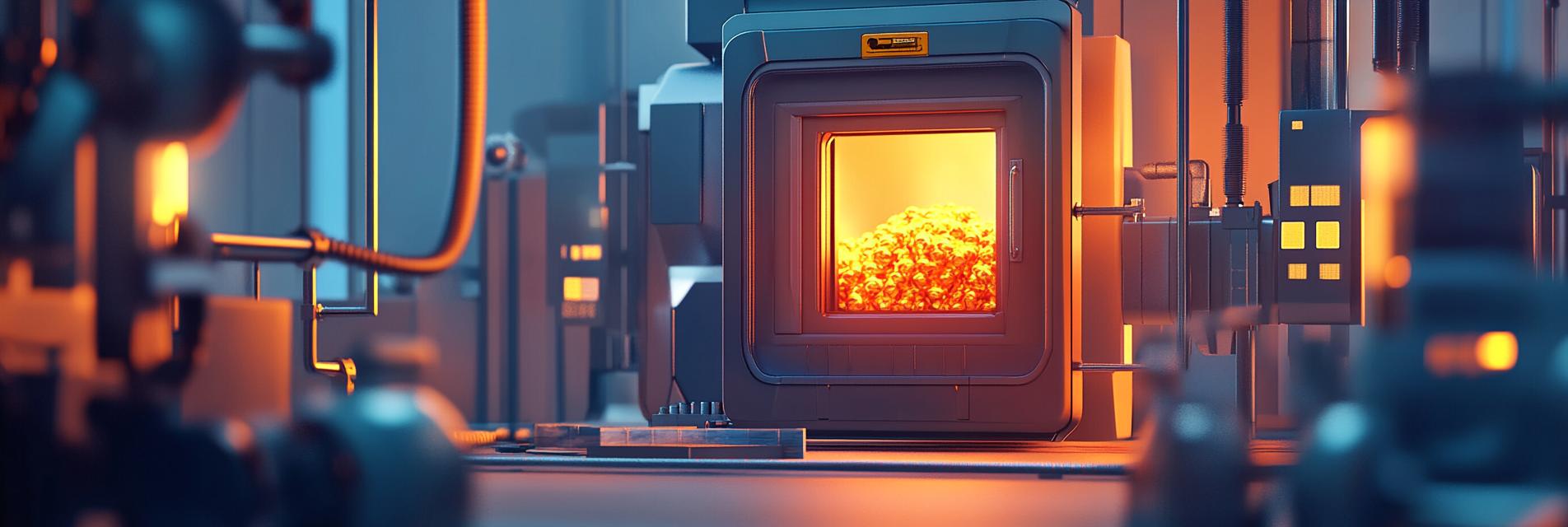

As a passionate industrial enthusiast, I have always been fascinated by the intricate processes that unfold in induction furnaces. One pivotal element that often goes unnoticed is the crucial role played by dry vibration materials. Today, I want to share my insights on how these materials contribute to the overall efficiency and stability of induction furnace operations. Let's delve into the key performance aspects together!

When we talk about dry vibration materials, we're referring to specialized compounds that are used to facilitate the effective melting and casting processes in induction furnaces. These materials not only withstand extreme temperatures but also maintain their structural integrity, thus ensuring consistent performance. The key characteristics include:

In my experience working with various industries, I've witnessed firsthand how the selection of dry vibration materials can make or break an operation. For instance, during a recent project, we switched from traditional methods to advanced dry vibration solutions, yielding a performance boost of over 30%. Not only was the melting time reduced, but the overall product quality saw significant improvement, reinforcing my belief in the value these materials bring to the table.

Understanding the performance of dry vibration materials in induction furnaces is not just about technical specifications; it's about recognizing their potential to transform industrial processes. I hope this journey through the world of dry vibration materials inspires you to appreciate the intricate details that contribute to successful operations in induction furnaces. Let’s continue to explore, innovate, and work together towards a more efficient future!