Product Details

Product Introduction

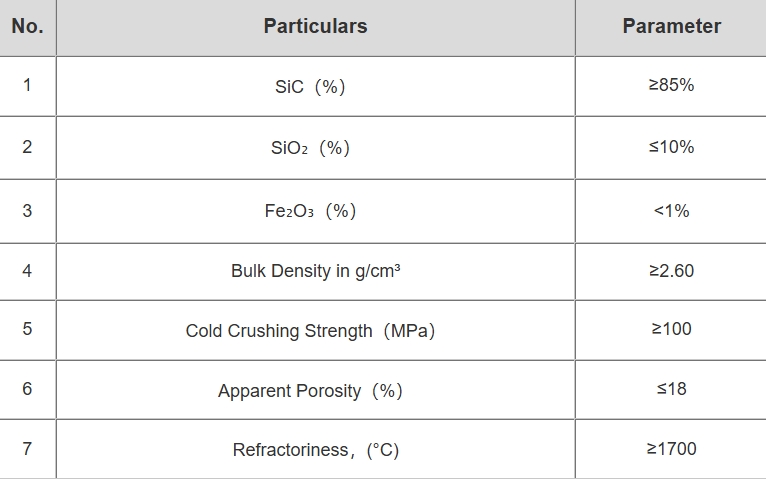

Our carbonized crucible bricks are designed for the most demanding high temperature applications. The bricks contain 98% high-grade silicon carbon, ensuring excellent durability and thermal shock resistance. Adopting a unique manufacturing process to ensure high purity and superior strength. These refractory bricks are widely used in heavy industries such as steel manufacturing, power generation and chemical processing, ensuring optimal performance and long-term use under extreme conditions. Its excellent wear resistance and antioxidant properties significantly reduce maintenance costs and downtime.

Advantages and features

1. Excellent thermal stability: After high temperature testing of 1700°C, our silicon carbon bricks maintain structural integrity under extreme heat, reduce deformation, and enhance the reliability of industrial applications.

2. Excellent wear resistance: The high-density composition and toughness of the bricks ensure their wear resistance, significantly reduce wear, extend service life, and bring about cost-effective operations.

3. Excellent thermal shock resistance: Our bricks are designed to withstand rapid temperature fluctuations, avoiding cracking and damage, ensuring uninterrupted production processes in high-demand environments.

4. High-purity ingredients: Manufactured using high-quality raw materials, silicon carbon bricks maintain high purity, helping to provide excellent performance in modern manufacturing environments and meet high standard requirements.

5. Global proven record: Successfully used in projects in more than 60 countries, our products have earned a reputation for excellence and reliability in key industries such as steel, power and chemicals.

Application Scenario

1. Steel Industry: Our refractory bricks play a key role in the steel manufacturing process, providing reliable and durable solutions for furnaces and converters that are subjected to extreme heat and pressure.

2. Power Production: These refractory bricks are ideal for boiler applications, ensuring efficient energy production while protecting boiler components from high temperature degradation.

3. Chemical Processing: Excellent corrosion resistance makes it suitable for use in various chemical processing environments, ensuring long-term use and reducing operating downtime.

4. Mining Operations: Our bricks are used in smelting furnaces and kilns to meet the demanding requirements of the mining industry, providing excellent resistance to wear and thermal shock.

5. Glass Manufacturing: Critical in the high-temperature glass melting and forming process, silicon carbon bricks improve productivity and operating efficiency.