Product Details

Product Introduction

Clay refractory bricks are designed to withstand extreme temperatures and harsh environments and are widely used in multiple industrial fields. Our refractory bricks exhibit excellent thermal stability, corrosion resistance and wear resistance, ensuring long-term reliability under harsh conditions. They are suitable for various equipment requiring high temperatures, such as blast furnaces, glass kilns, carbon furnaces, etc., providing optimal insulation performance and working efficiency. Through a focus on quality and innovation, Rongsheng refractory bricks can improve energy efficiency, reduce operating costs, and optimize the overall productivity of key manufacturing processes.

Advantages and features

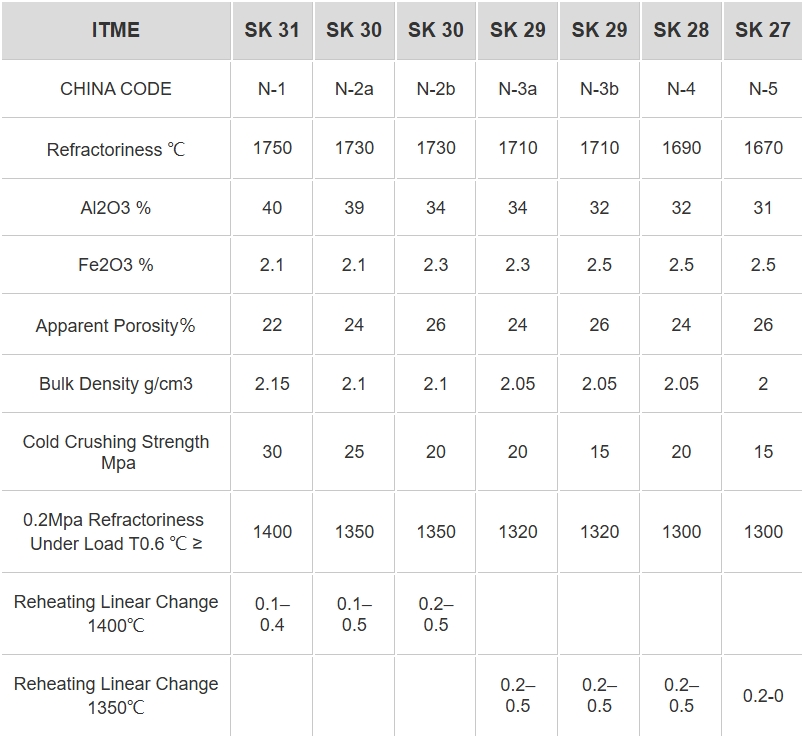

1. Superior thermal performance: Our refractory bricks can withstand temperatures up to 1750°C, ensuring reliable operation in extreme conditions without compromising structural integrity.

2. High Strength and Durability: With superior mechanical strength and wear resistance, these bricks maintain their shape and effect for a long time, reducing maintenance costs.

3. Excellent chemical resistance: Designed to withstand acid and alkaline environments, it is very suitable for use in harsh industrial processes, reducing damage rate and downtime.

4. Customizable Solutions: We offer a wide range of configurations and specifications, allowing customers to select the ideal refractory bricks based on their specific applications and requirements.

5. Proven industry performance: Our refractory bricks have been successfully used in many industries such as metallurgy and glass production, demonstrating their reliability and effectiveness.

Application Scenario

1. Steel industry: used in blast furnaces and converters to ensure optimal performance at high temperatures.

2. Glass manufacturing: Applicable to glass furnaces and kilns, where thermal stability and insulation are critical to product quality.

3. Non-ferrous metal smelting: used for high-temperature smelting of non-ferrous metals, helping to improve efficiency and sustainability.

4. Chemical Processing: Effective in chemical reactors and incinerators, where corrosion and thermal shock resistance are critical to durability.

5. Power generation: Applicable to high-temperature equipment in power plants, helping to improve energy efficiency and reduce operating costs.