Product Details

Product Introduction

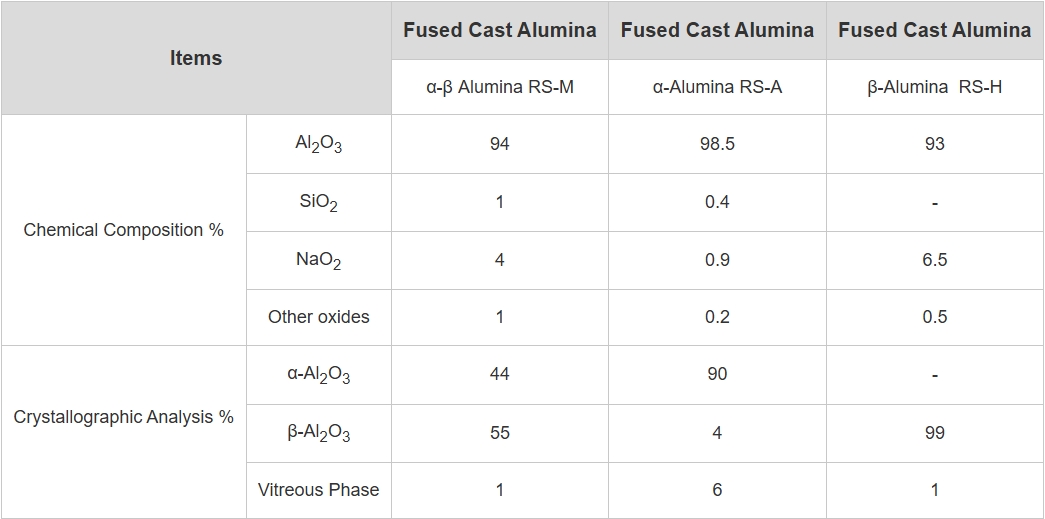

Fused corundum refractory bricks are designed to provide excellent durability and high temperature resistance in a variety of industrial applications. With an aluminum content of more than 90%, they exhibit excellent mechanical strength and thermal stability, making them ideal for critical parts of industrial furnaces that face extreme wear and high temperatures. Our products are known for their excellent load softening temperature, good chemical stability, and strong resistance to acidic and alkaline environments.

Advantages and features

1. Maximum durability: The aluminum content of our bricks exceeds 90%, providing excellent mechanical strength and heat resistance, significantly exceeding the performance of standard refractory materials, and is especially suitable for use in harsh conditions.

2. Chemical Resistance: Specifically designed to resist acidic and alkaline slags, our refractory bricks are ideal for environments where chemical stability is critical, ensuring long-term performance.

3. High load softening temperature: With a load softening onset temperature in excess of 1700°C, these bricks maintain structural integrity even under the most severe thermal conditions.

4. Diversified applications: Suitable for steel, cement, petrochemical and other industries, our refractory bricks can be customized according to different operating needs.

5. Advanced manufacturing: Using fully automatic and intelligent production lines, we ensure the consistency and accuracy of each brick to meet the strict requirements of modern industrial applications.

Application Scenario

1. Steel Industry: Our bricks are ideal for critical components of metallurgical furnaces and are designed to withstand high temperatures and mechanical stresses to ensure long-term operation.

2. Cement production: Used in rotary kilns and other high temperature cement processing applications, providing optimal performance and durability to ensure the quality of cement products.

3. Chemical processing: Suitable for high temperature areas such as reactor linings, providing excellent chemical resistance and durability to ensure effective operation.

4. Power generation: Suitable for use in waste incineration plants and other power generation facilities to improve the efficiency and reliability of operations.

5. Glass Manufacturing: Our refractory bricks are widely used in glass melting furnaces, which require high thermal stability and wear resistance to meet industry needs.