Product Details

Product Introduction

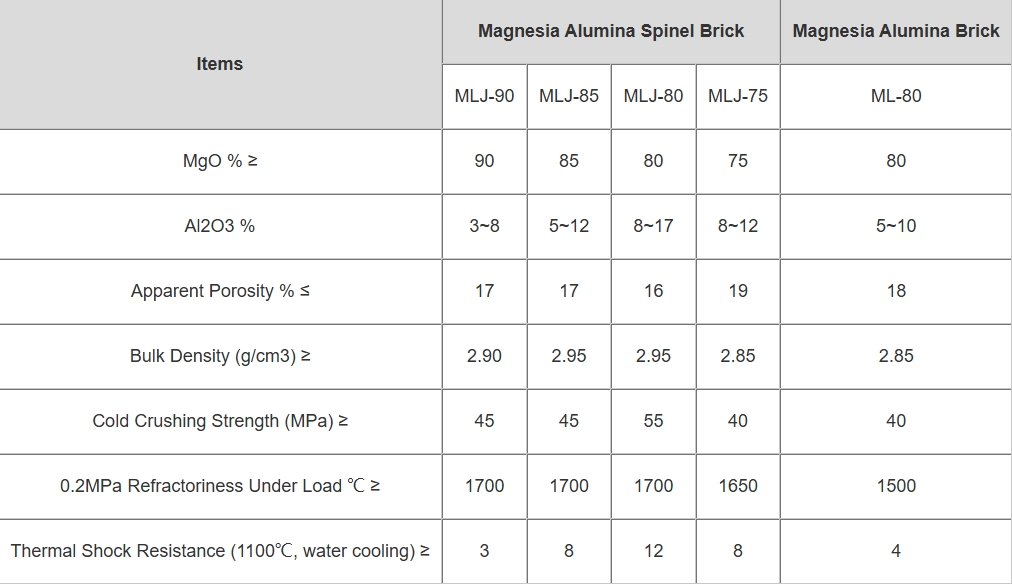

Rongsheng high alumina magnesium spinel refractory bricks are designed to withstand extreme temperatures and harsh conditions, and are perfectly suited for a variety of industrial applications. Made from high-purity molten magnesium and spinel, this brick ensures low impurity content and excellent thermal performance. Our refractory bricks are ideal for use in rotary cement kilns, glass kilns, and sintering operations for all types of refractory materials, providing excellent resistance to alkaline vapor corrosion and performing well in redox atmospheres. Our products not only meet the high standards of the industry, but also improve operational efficiency by extending service life and reducing maintenance costs. We are committed to innovation and technology to provide customers with solutions that can meet high temperature challenges and performance expectations.

Advantages and features

1. Excellent heat resistance: Our refractory bricks maintain structural integrity and performance at high temperatures exceeding 1700°C, suitable for the most demanding applications.

2. Low impurity content: By reducing the CaO level, our bricks reduce the risk of deterioration, thus ensuring a longer service life than traditional products.

3. Enhanced Corrosion Resistance: These bricks have excellent resistance to alkali vapor and SOx corrosion, improving reliability and reducing downtime.

4. Multifunctional application: Our products are suitable for many industries such as cement, glass, steel and chemical industry, and adapt to various high temperature environments.

5. Customized Solutions: We work closely with our customers to develop customized refractory solutions that meet their unique operational challenges and requirements.

Application Scenario

1. Cement Industry: Widely used in rotary kilns, providing durability and resistance to high temperatures and corrosive environments.

2. Glass manufacturing: very suitable for glass kiln furniture, with excellent thermal shock resistance and service life.

3. Metallurgical Application: Effectively used in hot metal mixing furnaces to ensure reliable performance under high pressure and high temperature.

4. Refractory sintering: Suitable for sintering kilns, providing enhanced structural integrity and performance.

5. Chemical Processing: Performs well in all types of chemical reactors, maintaining stability and performance under harsh conditions.