Product Details

Product Introduction

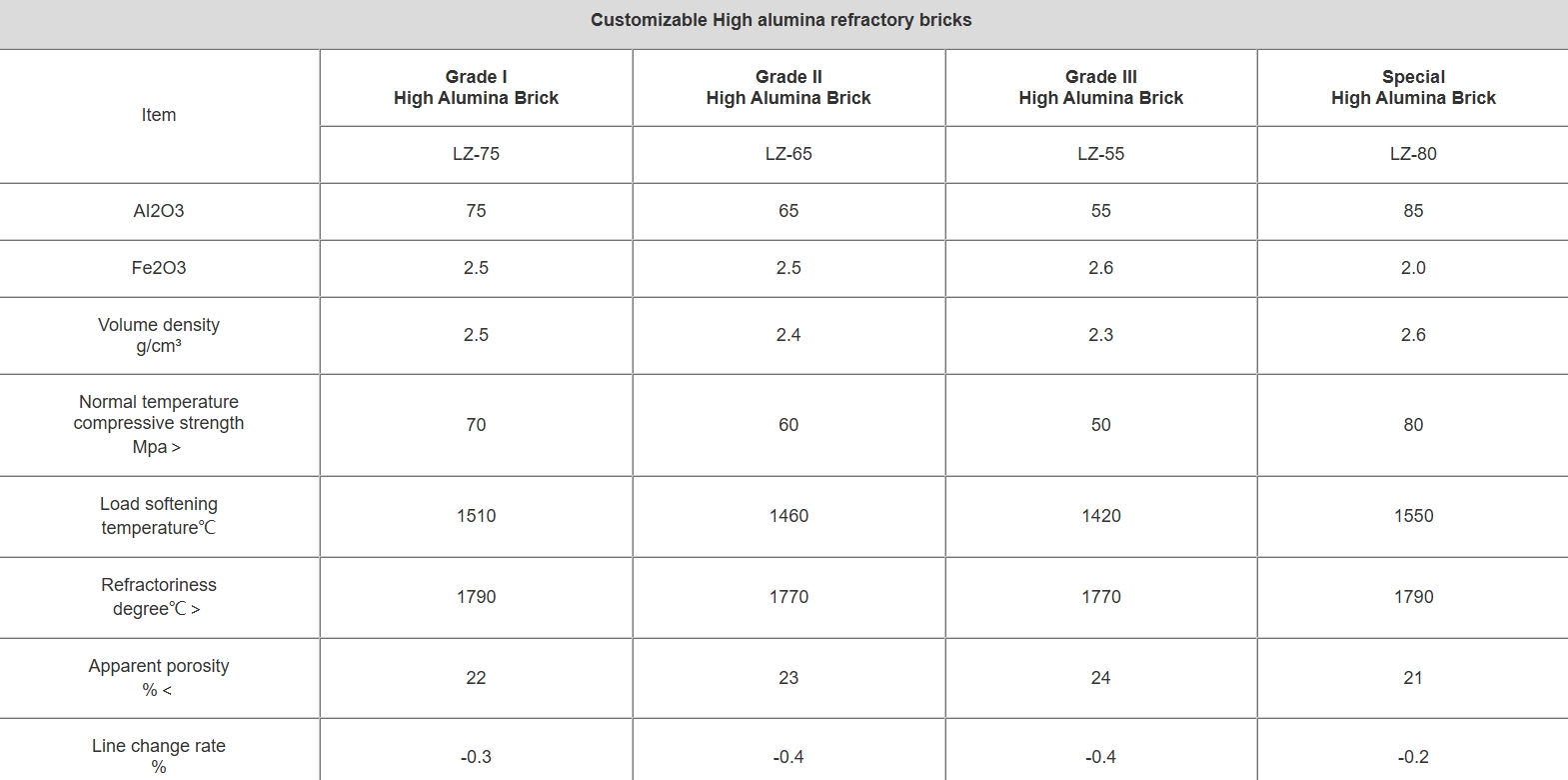

Rongsheng high alumina refractory bricks are designed for use in the most demanding high temperature environments, with a melting point of over 1700°C. These bricks are mainly composed of Al2O3, providing excellent thermal stability, low thermal conductivity and good acid and alkali corrosion resistance. Our bricks are used in a variety of industrial applications to ensure that different operating needs are met. With high mechanical strength and the ability to resist rapid temperature changes, these refractory bricks provide reliable insulation and reduce energy losses in industries such as metallurgy, power and chemicals. In addition, Rongsheng's commitment to quality ensures that each batch of products is produced according to strict manufacturing standards, thereby engineering products that are both high-performance and long-life.

Advantages and features

1. Excellent corrosion resistance: High aluminum content ensures excellent corrosion resistance in acidic and alkaline environments, extending the service life of the furnace lining.

2. High Melting Point: The performance threshold of refractory bricks exceeds 1700°C, making them suitable for high temperature applications in a variety of industries.

3. Excellent thermal stability: Our bricks are less prone to cracking when the temperature changes rapidly, making them very suitable for thermal cycling environments.

4. Low thermal conductivity: effectively retains heat, reduces energy loss, and improves the overall efficiency of industrial processes.

5. Reliable performance: Our refractory bricks are successfully used in more than 80 countries, and industry leaders trust their reliability.

Application Scenario

1. Metallurgy: Ideal for lining of blast furnaces, hot blast furnaces and electric furnaces, providing necessary thermal insulation and protection.

2. Power Generation: Used in combustion chambers and flue walls to ensure durability and efficiency in high-temperature energy production.

3. Chemical industry: effectively lining reactors and firing furnaces, resisting corrosive materials and ensuring high performance and service life.

4. Construction: Suitable for thermal insulation in various structural applications to improve the energy efficiency of building projects.

5. Glass industry: Withstands extreme temperatures during melting and forming processes, providing reliable performance and quality control.