Product Details

Product Introduction

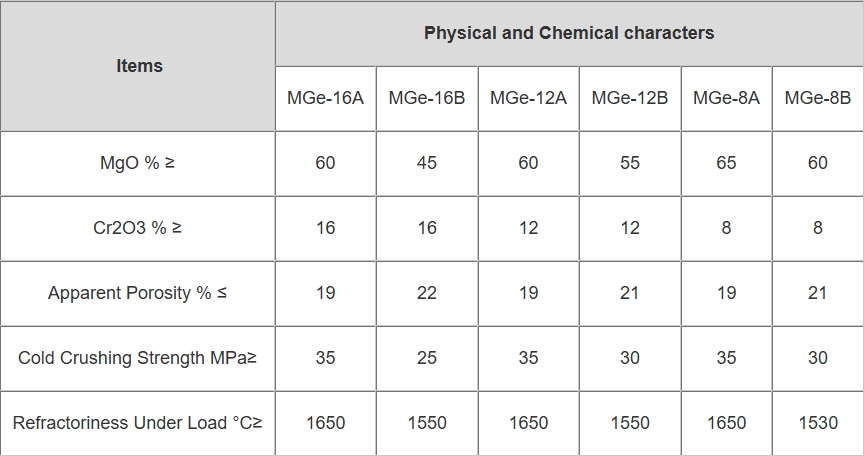

High performance magnesia chrome refractory bricks are designed for extreme thermal environments, providing exceptional resistance to high temperatures and corrosion. These bricks play a key role in a variety of high temperature applications, especially in the metal and glass industries. With their excellent refractoriness and low creep rate, they ensure long-lasting performance under significant thermal stress. Suitable for use in electric arc furnaces, glass melting furnaces and rotary cement kilns, our magnesia chrome bricks provide a stable and reliable refractory solution. Each product is manufactured using advanced technology and high-quality raw materials, ensuring consistency and reliability in every unit. Our commitment to technological innovation and operational excellence makes our bricks not just a purchase, but an investment in quality and performance.

Advantages and features

1. Excellent thermal stability: Magnesia-chrome bricks can withstand high temperatures exceeding 1550°C, ensuring structural integrity under extreme conditions.

2. Excellent corrosion resistance: They resist damage from molten steel and glass, extending their service life in demanding applications.

3. Low creep rate: With minimal deformation under load, these bricks retain their shape and properties over long periods of use.

4. Customized Designs: We offer customizable shapes and grades to meet specific customer needs and applications.

5. Proven Record of Excellence: Our products have successfully served leaders in the steel and glass industries, ensuring reliability and performance.

Application Scenario

1. Metal Industry: Ideal for use in electric arc furnaces and steel smelting, providing durability and thermal management capabilities.

2. Glass Manufacturing: Ensures reliable operation in glass melting furnaces and is resistant to high temperatures and chemical attacks.

3. Cement production: Suitable for rotary kilns to effectively manage extreme thermal cycles and wear.

4. Non-ferrous metals: provide the required high temperature resistance for the smelting process.

5. Chemical Processing: Operate effectively in various high-temperature chemical reactions to extend the service life of processing equipment.