Product Details

Product Introduction

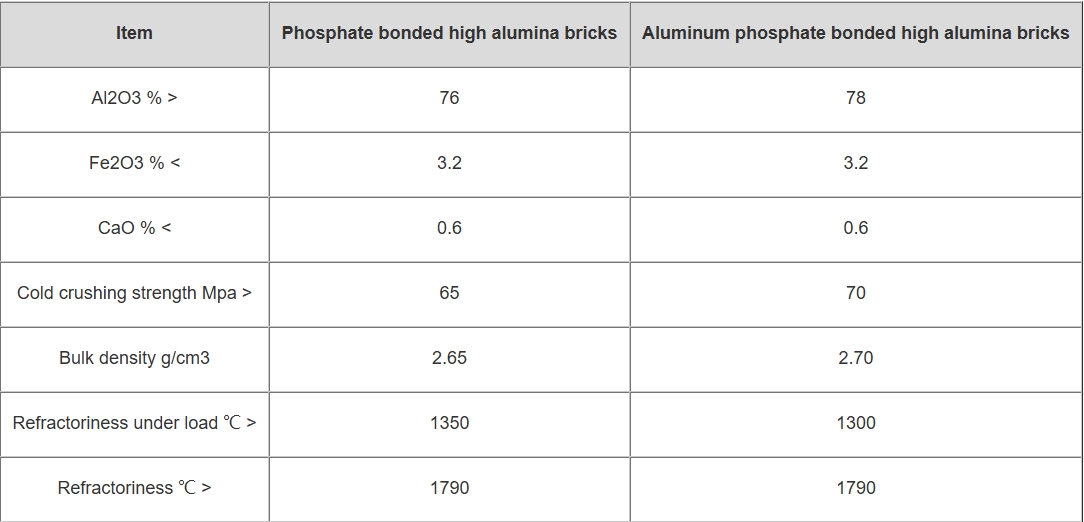

Our high-performance phosphate-bonded high-alumina bricks are designed to provide excellent performance in high-temperature applications, especially for cement kilns. Made from high-quality bauxite clinker and advanced phosphate or aluminophosphate binders, these bricks are designed to withstand extreme thermal conditions and mechanical stress. With high mechanical strength and excellent thermal shock resistance, our products can ensure service life and reliability in harsh environments. They perform well in the transition zone, roasting zone and other key areas of cement kilns, effectively preventing early wear and improving working efficiency. Thanks to years of innovation and research and development, our phosphate-bonded high-alumina bricks meet strict quality standards and are tailored to provide stable and reliable performance, becoming a basic material for industries that rely on high-temperature processes.

Advantages and features

1. Excellent mechanical strength: Our bricks have strong compressive strength, ensuring stable performance under extreme conditions, improving operational confidence.

2. High thermal shock resistance: Designed to withstand rapid temperature fluctuations, reducing the risk of spalling and ensuring long-term durability in thermal applications.

3. Customized for cement kilns: Specially developed for cement kilns, with optimal performance in transition and cooling zones, improving operating efficiency.

4. Advanced chemical bonding: Proprietary phosphoric acid and aluminum phosphate binders are used to ensure the structural integrity and resistance to chemical attack of the brick.

5. Widely recognized quality: Trusted by the global industry, our products undergo strict quality control to ensure high performance and customer satisfaction.

Application Scenario

1. Cement industry: Applicable to various kiln areas in cement production, ensuring high performance and extending service life.

2. Power generation industry: suitable for use in high temperature areas of power generation equipment to optimize energy efficiency.

3. Metallurgical Applications: Effective in metal production and processing, providing the necessary high temperature resistance.

4. Chemical Manufacturing: Ensure safety and efficiency in high-temperature chemical environments and ensure operational stability.

5. Fire-resistant applications: It is also widely applicable in other industries that need to withstand high heat and mechanical pressure.