Product Details

Product Introduction

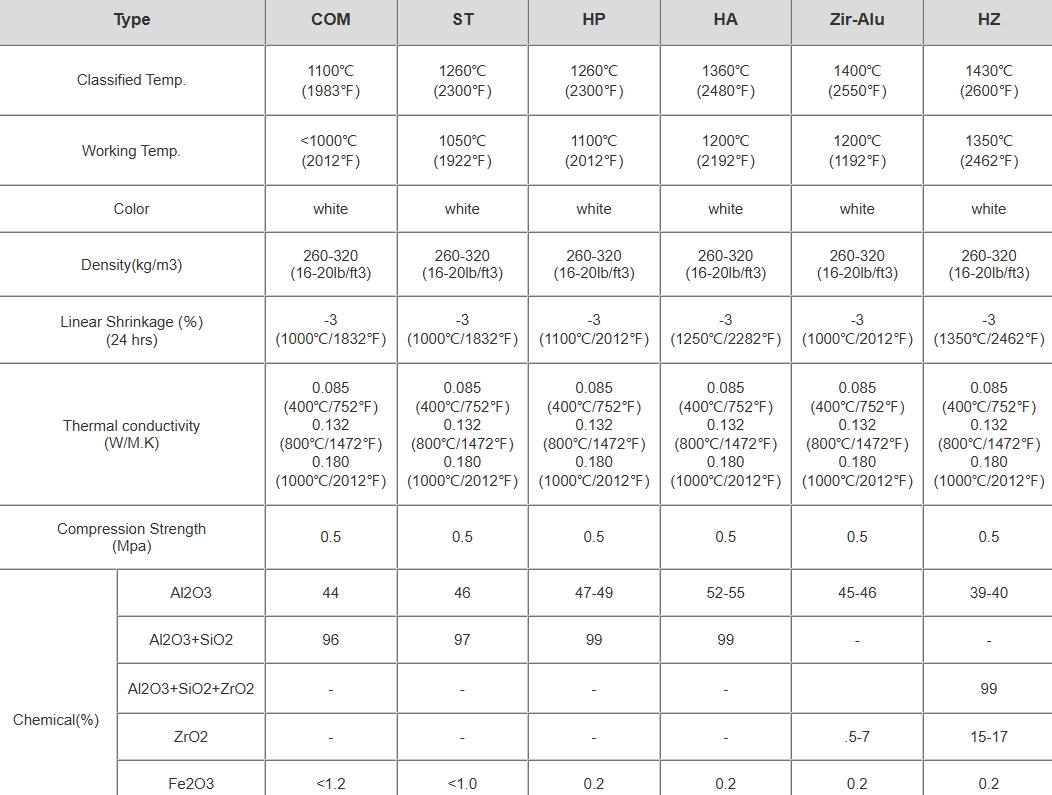

Our high-performance refractory ceramic fiberboard is designed for high-temperature environments, with excellent thermal insulation properties and superior strength. Suitable for a variety of industrial applications, it can effectively resist thermal shock and chemical attack, and is very suitable for lining furnaces, boilers and pipelines. Its versatile temperature range and enhanced density ensure that energy losses are minimized at optimal performance. As a result, you benefit from reduced operating costs and extended maintenance intervals. Our advanced manufacturing process uses high-quality materials to ensure that the structural integrity of the fiberboard remains consistent even under extreme conditions.

Advantages and features

1. Excellent thermal insulation performance: Our ceramic fiberboard effectively reduces heat loss, ensures maximum energy efficiency and reduces operating costs.

2. High temperature adaptability: Withstands temperatures up to 1430°C, suitable for industrial furnaces and high-intensity environments, ensuring durability and reliability.

3. Lightweight and flexible: Lightweight and easy to handle and install, the lightweight characteristics of the board do not affect its mechanical strength, and it can be applied quickly and efficiently.

4. Thermal shock resistance: Designed to withstand rapid temperature fluctuations, prevent cracks or structural failure, and provide stable operating performance.

5. Environmentally friendly materials: Made of non-toxic materials, our refractory ceramic fiberboard is a sustainable choice that meets industry requirements and contributes to protecting the earth.

Application Scenario

1. Steel Industry: Provide optimal insulation during steel manufacturing, improve energy efficiency and product quality, and ensure effective heat retention.

2. Chemical Processing: Suitable for use in chemical reactors and boilers, the panels provide strong thermal insulation when exposed to corrosive chemicals.

3. Power generation industry: Very suitable for thermal insulation of turbines and boilers, effectively improving energy conservation and operating efficiency.

4. Glass Manufacturing: Maintaining high temperatures during melting operations is key to improving product quality control and consistency.

5. Non-ferrous metal production: Suitable for transfer applications in non-ferrous metal processing to improve efficiency and reduce heat loss.