Product Details

Product Introduction

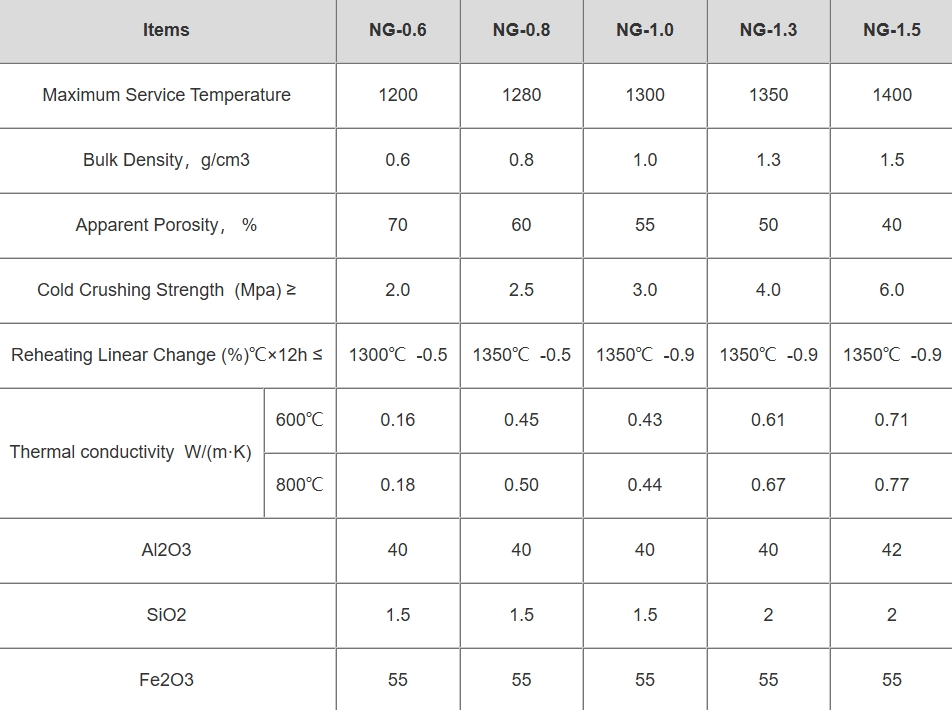

High-temperature lightweight refractory clay insulation bricks are specially designed for high-temperature applications in various industries. Made from a unique formula of high-quality bauxite and plastic clay, they have a good pore structure and provide excellent thermal insulation and low thermal conductivity. The maximum service temperature of these insulation bricks can reach 1400°C, which can effectively save energy and reduce equipment safety and improve efficiency. They are ideally suited for applications in the steel, cement, glass and power industries and can bring significant cost savings to the production process. Its excellent thermal shock resistance and mechanical strength ensure a longer service life, making it a reliable choice in industrial heating environments.

Advantages and features

1. Excellent thermal insulation properties: Our lightweight refractory bricks provide excellent thermal insulation properties, significantly reducing heat loss and reducing energy consumption in industrial operations.

2. High Service Temperature: These bricks are capable of withstanding maximum operating temperatures up to 1400°C, making them widely suitable for a variety of high temperature applications.

3. Lightweight composition: The low density of these bricks allows for lightweight construction, reducing the overall weight of kilns and furnaces, thereby saving on structural costs.

4. Cost-effective: Utilizing abundant raw materials, our lightweight refractory bricks offer an economical option without compromising on quality, ensuring a high return on investment.

5. Proven Performance: With a proven track record in different applications, our bricks are successfully used in industries ranging from power generation to metallurgy.

Application Scenario

1. Steel Industry: Lightweight refractory bricks are ideal for use in the steel manufacturing process, where high temperature durability and thermal insulation are critical.

2. Cement Production: These bricks can improve the performance of kilns in cement production, enhance operational efficiency and energy conservation.

3. Glass Manufacturing: Ensuring optimal thermal efficiency, our lightweight refractory bricks are a reliable choice for lining glass melting furnaces.

4. Chemical Processing: Suitable for maintaining necessary high temperatures, these insulation bricks are widely used in chemical reactors and related equipment.

5. Power Generation: Suitable for a variety of furnace applications within the power industry, promoting efficiency and reducing costs.