Product Details

Product Introduction

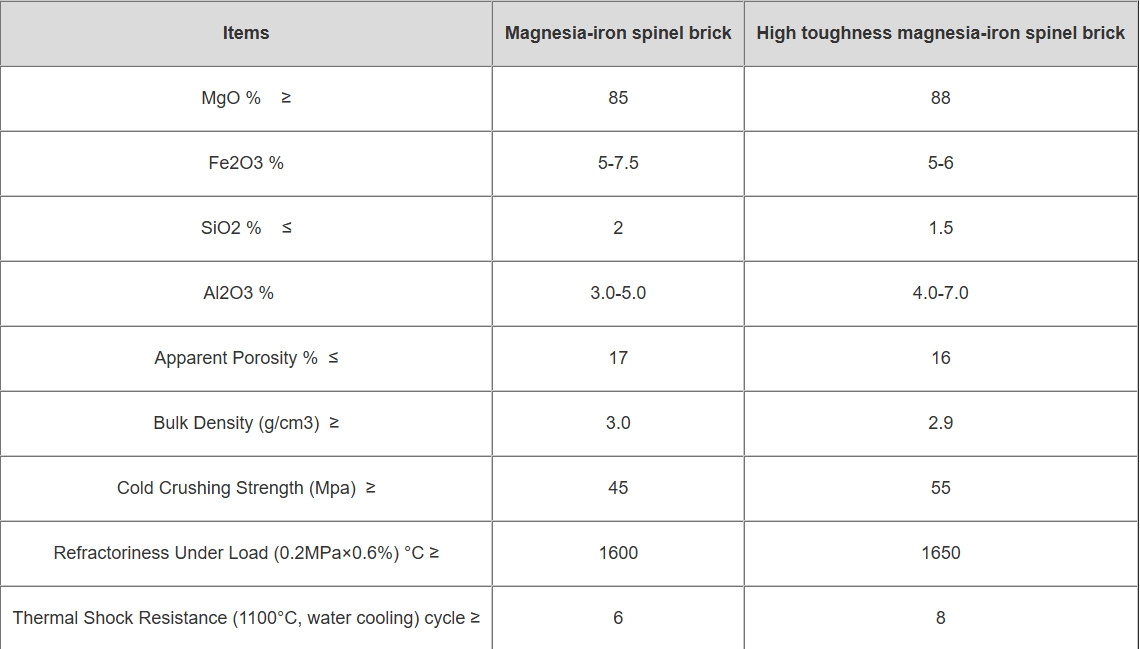

Magnesia-iron spinel refractory bricks are an advanced refractory material designed for high temperature applications, especially for cement kilns. Manufactured from high purity magnesium and aluminum-iron spinel, these bricks have excellent thermal shock stability and corrosion resistance. With a melting point of over 1600°C, they effectively insulate and protect the kiln lining, enhancing the durability and efficiency of the furnace. The unique properties of these bricks minimize hexavalent chromium contamination, making them a safe and environmentally friendly choice for industrial applications. Suitable for a variety of high temperature environments, our magnesium-iron spinel bricks can improve operating performance, reduce energy consumption, and extend service life, ensuring you get the maximum return on your investment.

Advantages and features

1. Excellent thermal stability: Our magnesia spinel bricks maintain high performance under extreme temperatures, effectively reducing thermal fatigue and potential failures.

2. Environmentally Friendly Composition: Free of hexavalent chromium, these bricks support your sustainability commitment while complying with strict industry standards.

3. Wide application: Suitable for many high-temperature industrial environments such as cement, steel, chemical industry, etc., ensuring wide use.

4. Enhanced Durability: Designed to withstand harsh conditions, our refractory bricks provide long-lasting performance, significantly reducing replacement costs.

5. Superior corrosion resistance: These bricks resist chemical and physical degradation, protecting kiln integrity and reducing the need for maintenance.

Application Scenario

1. Cement industry: Especially suitable for cement kilns, providing stability and durability, thereby improving overall production efficiency.

2. Steel production: Suitable for high temperature environments, ensuring durability and reliability is essential for operational effectiveness.

3. Chemical Manufacturing: Provides excellent thermal insulation and protection in reactors and furnaces to ensure process integrity.

4. Glass industry: suitable for high temperature glass melting furnaces, ensuring optimal performance and energy saving.

5. Waste Incineration: Effective in high temperature waste management applications, balancing performance and environmental safety.