Product Details

Product Introduction

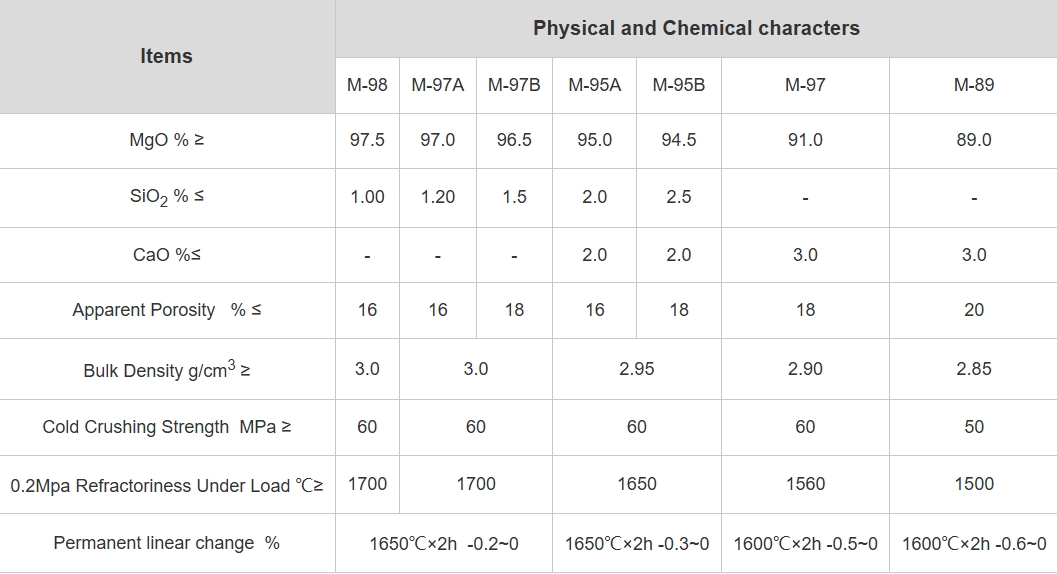

Made from molten and sintered magnesium, our high-performance magnesia refractory bricks offer superior thermal resistance and durability at temperatures exceeding 1600°C. Designed to withstand extreme corrosive environments, these bricks provide a rugged solution for a wide range of industries including steel manufacturing, non-ferrous metal smelting and cement production. Their excellent thermal stability minimizes cracking during extreme temperature fluctuations, making them ideal for high-temperature processes. In addition, with their high compressive resistance, our magnesia bricks maintain excellent mechanical strength under severe operating loads. These properties enable customers to achieve optimal performance while reducing downtime and maintenance costs. Partner with us to increase production efficiency and reliability with advanced refractory solutions.

Advantages and features

1. Excellent refractory performance: Our magnesia bricks can withstand extreme temperatures exceeding 1600°C, ensuring reliability in demanding applications.

2. Super corrosion resistance: Specially formulated to resist strong alkali and molten metal, extending the service life of the furnace lining and reducing downtime.

3. Excellent thermal stability: Designed for rapid temperature changes without cracking, ensuring stable performance in dynamic environments.

4. High Mechanical Strength: Maintaining strength under high load conditions, our bricks can handle demanding applications without compromising structural integrity.

5. Multi-purpose applications: Suitable for multiple industries such as steel, glass and cement, providing a personalised solution for high temperature challenges.

Application Scenario

1. Steel industry: Ideal for use in electric arc furnaces and converters, improving efficiency and durability in the steel production process.

2. Non-ferrous metal smelting: suitable for aluminum and copper smelting which require high corrosion resistance furnaces to maintain stable performance.

3. Cement industry: Rotary kilns used in cement production provide reliable thermal protection and reduce energy loss.

4. Power Production: As an effective insulation material and lining for boilers, improving efficiency and extending service life under severe operating conditions.

5. Glass Manufacturing: Best suited for glass melting furnaces, ensuring high thermal performance and structural support under extreme temperatures.