Product Details

Product Introduction

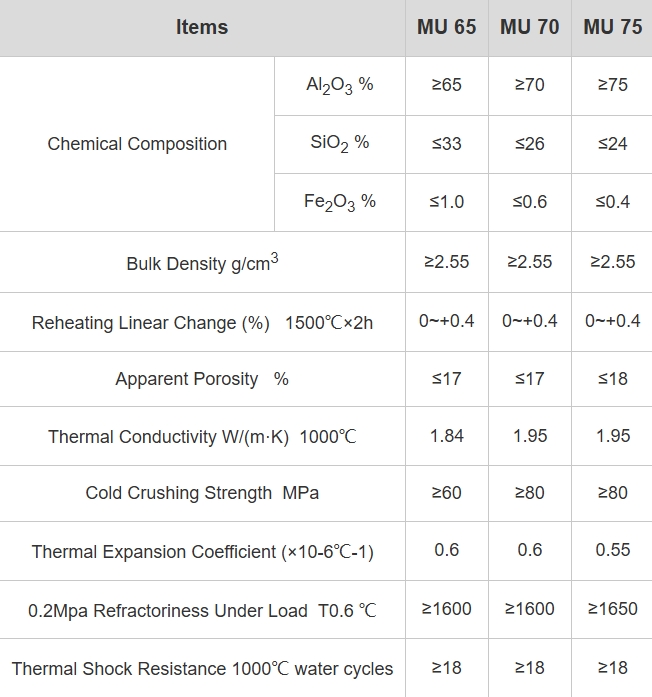

Mullite refractory bricks are high-performance materials designed for extreme heat applications. With a bauxite content of 65% to 75%, they exhibit excellent thermal shock resistance and strength. They are ideal for use in important areas such as furnace gasifiers and ammonia reformers. Our advanced manufacturing process ensures high quality and consistency, making them the first choice for industries that require reliability in high temperature conditions.

Advantages and features

1. Superior thermal stability: Our corundum mullite bricks can withstand extreme temperatures up to 1790°C, ensuring extremely reliable performance in high-temperature applications.

2. Excellent thermal shock resistance: These bricks exhibit high thermal shock resistance, reducing the risk of cracking, extending service life and adapting to the needs of dynamic thermal environments.

3. High compressive strength: Our refractory bricks are designed with strong structural integrity and maintain a cold compressive strength of 60-260MPa, ensuring reliability under harsh conditions.

4. Low apparent porosity: With an apparent porosity of ≤17%, it improves the insulation effect, reduces energy loss, and promotes overall operating efficiency.

5. Wide Applicability: Our products are used in various industries such as steel, cement, glass and chemicals, proving their versatility in a wide range of applications.

Application Scenario

1. Steel Industry: Ideal for use in furnaces and cast iron ladles, providing exceptional durability and thermal efficiency at extremely high heat.

2. Glass Industry: Applicable to glass melting furnaces to ensure optimal performance and durability under high pressure conditions.

3. Cement industry: Used in kilns and preheaters to improve production efficiency and reduce maintenance downtime.

4. Non-ferrous smelting: Indispensable in smelting furnaces, providing strong performance and resistance to the corrosive environment of smelting operations.

5. Chemical industry: suitable for reactors and high temperature processes, providing reliability in harsh chemical environments.