Product Details

Product Introduction

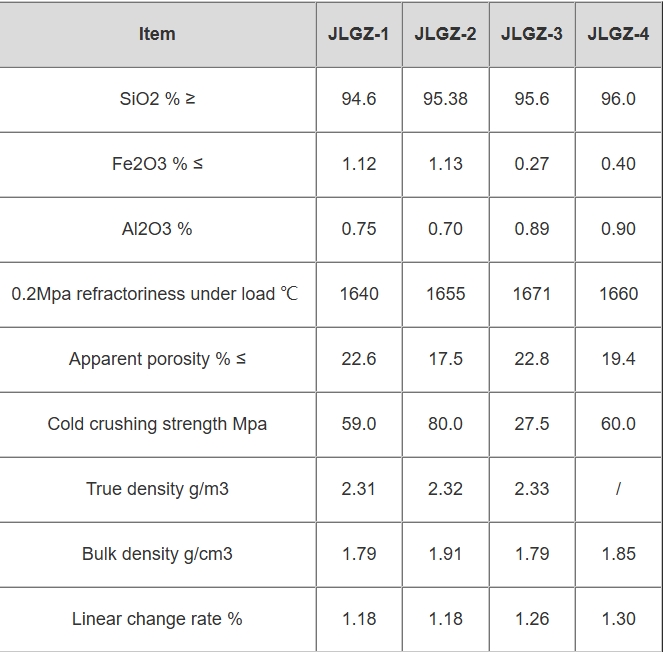

The silica bricks we launch are specially designed for high temperature applications and their main component is SiO2. These bricks have excellent thermal stability, with a melting point of over 1700°C, making them particularly suitable for use in high-temperature environments such as coke ovens and glass melting tanks. Refractory bricks have excellent acid etching resistance and low thermal conductivity, effectively provide insulation and significantly save energy consumption. The unique crystal structure (containing silica) ensures excellent durability and stability under rapid temperature changes. Our refractory bricks not only meet industry standards but exceed them, providing the best solution for manufacturers seeking high reliability and performance.

Advantages and features

1. Excellent thermal performance: High melting point and low thermal conductivity optimize energy efficiency, ensuring better thermal insulation and significant energy saving in high temperature applications.

2. Excellent durability: Enhanced thermal shock and chemical corrosion resistance ensures longer service life and reduces maintenance costs.

3. Diversified applications: Suitable for metallurgy, glass, petrochemical and other industries to meet different high temperature requirements.

4. Proven performance: Relying on extensive research and cooperation with top universities to ensure that our technology is cutting-edge and innovative.

5. Comprehensive support: Provide full life cycle services from initial consultation to installation and ongoing support, tailored to meet customer needs.

Application Scenario

1. Metallurgical industry: used in coke oven process and steel smelting furnace lining to improve durability and operational efficiency.

2. Glass Industry: Ideal for use in high temperature areas of glass melting furnaces to ensure product purity and structural integrity.

3. Petrochemical industry: suitable for applications in extreme temperatures and harsh chemical environments, with good temperature resistance.

4. Power Generation Industry: Used in energy production facilities, high-performance refractory materials are critical to successful operations.

5. Construction industry: used to produce advanced building materials that require high thermal stability and strength.